Our Product

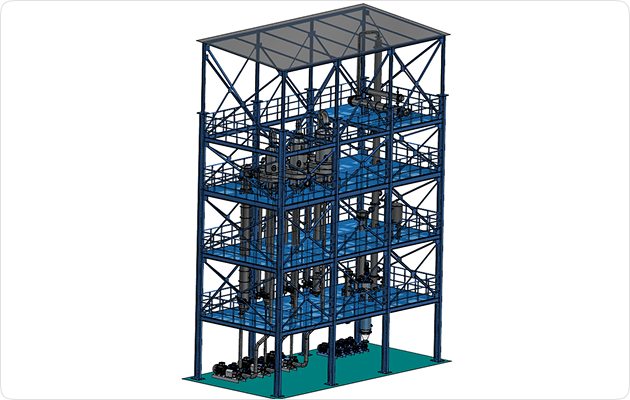

Packaged Sewage Treatment Plants (STP)

Design, Supply & Commissioning (5 KLD to 200 KLD)

We offer a complete range of Packaged Wastewater Treatment Plants designed using ASP, MBBR, SBR & MBR technologies. These systems are tailored to meet your specific requirements and are available in standard capacities:

📏 Standard Capacities Available:

5 KLD, 10 KLD, 20 KLD, 30 KLD, 40 KLD, 50 KLD, 60 KLD, 75 KLD, 90 KLD, 100 KLD, 150 KLD, 200 KLD

🔧 Design & Technical Features:

- Material of Construction: Mild Steel Epoxy Painted (5 mm thick) or FRP 2-3 mm

- Corrosion Resistance: Epoxy coating of 150–200 microns or FRP body

- Smart Flow Control: Advanced level sensor algorithm ensures precision

- Standby Arrangements: For uninterrupted performance

- Water Reuse: Treated water can be reused for gardening or toilet flushing

📦 What’s Included in the Package?

Component

- Process Tanks

- Process Piping

- Feed Pump (Self-Priming, Non-Clogging)

- Twin Lobe Roots Blower

- Return Sludge Pump (Non-Clogging)

- Filter Feed Pump (Self-Priming)

- Fine Bubble Diffusers

- Pressure Sand Filter (PSF)

- Activated Carbon Filter (ACF)

- Disinfection Unit

- PSF & ACF Auto Backwash

- Control Panel

Specification / Make

- As per design

- UPVC, As per design

- Lubi/CRI/CG

- Akash/ USHA / TMVT / AI / Everest

- Lubi/CRI/CG

- Lubi/CRI/CG

- EPDM tube/circular, Jetage / Techpro / Standard

- Polyglass / FRP / Vessel, Pentair / Avantura

- Iodine number 1000, Certified (ACF grade)

- UV or Sodium Hypochlorite – as per design

- Optional

- Semi-Automatic IP45 / fully automatic

Packaged Effluent Treatment Plants (ETP)

Design, Supply & Commissioning (5 KLD to 90 KLD)

Our off-the-shelf technology-based system is designed to deliver efficient pollutant reduction tailored to specific industry needs.

🧪 Our Design Methodology Includes:

- Wastewater Parameter Testing

- Design Flowrate

- Design Load & Site Considerations

- 3D Layouts & P&ID

⚙️ Technologies & Process Trains Offered

- Primary Clarification: Lamella, Circular Clarifiers, Settling Tanks

- Dissolved Air Flotation (DAF) or Flocculators

- Aerobic Treatment: ASP, Extended Aeration, MBBR, MBR, A2O

- Anaerobic Treatment: CSTR, UASB

- Advanced Oxidation: UV + H₂O₂, Fenton's Reagent, etc.

📏 Standard Capacities Available:

5 KLD, 10 KLD, 20 KLD, 30 KLD, 40 KLD, 50 KLD, 60 KLD, 75 KLD, 90 KLD

📦 What's Included in the Package?

Component

- Process Tanks

- Process Piping

- Feed Pump (Self-Priming, Non-Clogging)

- Twin Lobe Roots Blower

- Return Sludge Pump (Non-Clogging)

- Filter Feed Pump (Self-Priming)

- Fine Bubble Diffusers

- Pressure Sand Filter (PSF)

- Activated Carbon Filter (ACF)

- Disinfection Unit

- PSF & ACF Auto Backwash

- Control Panel

Specification / Make

- As per design

- UPVC, As per design

- Lubi/CRI/CG

- Akash/ USHA / TMVT / AI / Everest

- Lubi/CRI/CG

- Lubi/CRI/CG

- EPDM tube/circular, Jetage / Techpro / Standard

- Polyglass / FRP / Vessel, Pentair / Avantura

- Iodine number 1000, Certified (ACF grade)

- UV or Sodium Hypochlorite – as per design

- Optional

- Semi-Automatic IP45 / fully automatic

(Electric Based / Steam Based) for High TDS Wastewater

These are ideal for ZLD (Zero Liquid Discharge) systems where water needs to be removed from high-TDS or high-COD wastewater. Perfect for smaller industries or batch processing.

⚙️ Features:

- Energy Source: Electrical heaters or steam-operated jackets/tube bundles

- Material of Construction: SS316L / SS304 or as per chemical compatibility

- Compact Design: Skid-mounted & containerized options available

- Fully Automated: With flow and temperature control systems

- Condensate Recovery: With optional polishing system for reuse

📍 Best Suited For: Ceramic, pigment, printing, pharma intermediate units, dyes manufacturing, resin and other..

Multiple Effect Evaporators (MEE)

For Large Scale ZLD Systems

Our MEE systems are engineered for high efficiency and low steam consumption. These are ideal for bulk wastewater reduction with maximum resource recovery.

⚙️ Key Highlights:

- Available Configurations: 2 to 5 effect setups

- Energy Saving: TVR, MVR, and thermo-compressor integration

- Construction: SS316L, Duplex steel, or as per requirement

- Automation: SCADA/PLC-enabled controls

- Crystal/Slurry Separation: Add-on modules available

📍 Industries: APIs, dyes, distilleries, textiles, ceramics, solvent recovery unit and other

Solvent Strippers

For VOC & Solvent Recovery in Effluents

Solvent strippers are specialized units for removing and recovering solvents from effluents—common in pharma, dye intermediates, and chemical units.

⚙️ Features:

- Construction: SS316L / Glass-lined options

- Design Basis: Fractional distillation column or packed bed based

- Automation: Temperature, pressure & reflux ratio controlled

- Applications: DMF, THF, IPA, Acetone, Toluene etc recovery

- Capacity Range: Customizable based on solvent type and load

📍 Compliance: Designed to meet hazardous waste and VOC emission standards